In-Line Automatic System | Blow Dry - Filling - Capping | FILLING CAPPING MACHINE

Category:

FILLING / CAPPING MACHINE

Rotary Rinsing Module

- S/S 304 structure + guide plate + brackets

- S/S 304 adjustment stand

- 3.5″ Stainless steel torque chain conveyor ( c/w 1/4 HP motor with gear box + Delta inverter )

- AirTac cylinders & valve

- Country Origin: Malaysia

Automatic 6 nozzles Piston Filling Machine

- S/S 304 structure + Acrylic Plate & Bracket

- 6 stations piston filling with S/S 316 cylinders

- 6 nozzle sets S/S 316

- 3.5″ Stainless steel torque chain conveyor ( c/w 1/4 HP motor with gear box + Delta inverter )

- Capacity: 12~18 bottles/min

- AirTac cylinders & valve

- Country Origin: Malaysia

Automatic Capping Machine

- Vibrator Bowl

- S/S 304 Cap Feeder Track

- AirTac cylinders & valve

- 3.5″ Plastic Torque Chain Conveyor ( c/w 1/4 HP motor with gear box + Delta inverter )

- 2 Cap Tightening Heads

- S/S 304 Structure + Acrylic Plate & Bracket

- 90W Cap Tightening Motor

- Cap Tightening Toque Control Coupling

- Country Origin: Malaysia

Feeding Conveyor

- 3.5″W Stainless steel Torque Chain Conveyor ( c/w 1/4 HP motor with gear box + Delta inverter )

- SS 304 Structure + guide plate + brackets

- Air Tac cylinders & valve

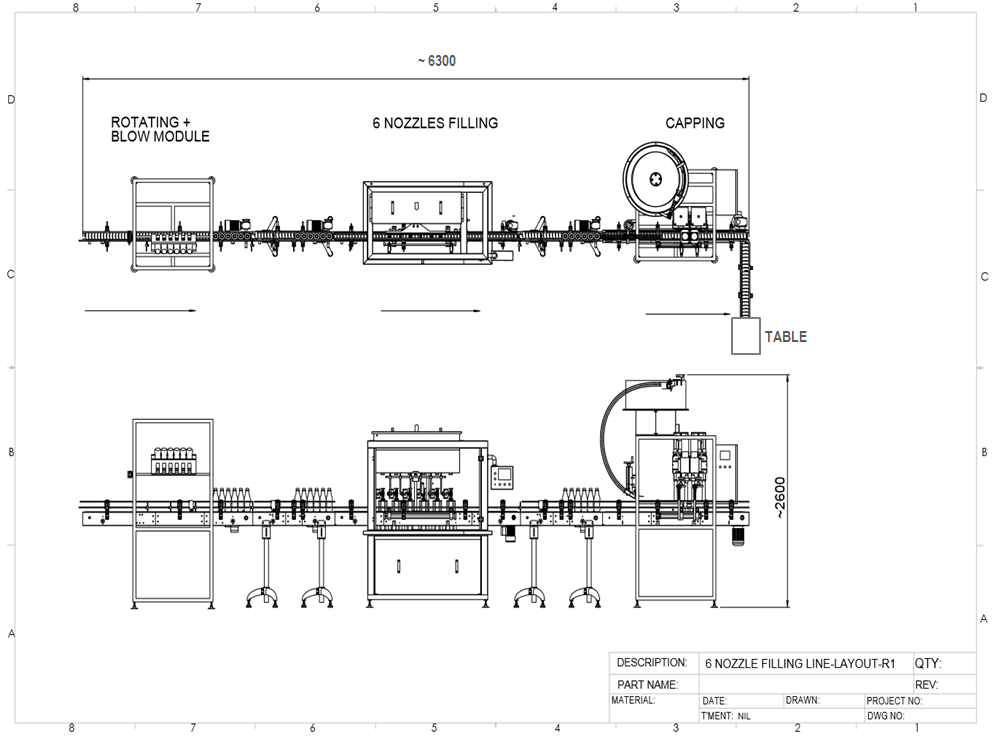

Layout Drawing

Scope of Application

- Liquid

- Sauce

Form of Packaging

.jpg)

Untitled

Inquiry - In-Line Automatic System | Blow Dry - Filling - Capping | FILLING CAPPING MACHINE