Description

Optional Accessories

Machine Structure and Feature

- Compact, solid, reliable, stable, low noise, and high efficiency.

- Bucket conveyor as filling system.

- PLC operation with touch screen control.

- Photoelectric sensor control system.

- Stepper motor to control film feeding system, higher accuracy.

- Inverter to control motor speed, resulting a stable operation, lower noise, and lower failure rate.

- Digital temperature controller, easy to operate.

- Auto counting system, easy to monitor quantity of output.

- Automatic measuring, filling, sealing, and date code printing.

- Same machine can be used for different bag width by changing the former.

- Bag length is controlled on screen display.

- For Linking-Style sachet, pneumatic cutting system will be used.

Optional Accessories

- Hole Punching Device

- Sachet Linking Device

- Easy Tear Device

Optional Equipment

- Check Weigher

- Metal Detector

- Air Compressor

Scope of Application

- Jelly, candy, biscuits, dehydrated fruit slice, key chain, hardware parts, etc

| Model | EM - 280B |

| Product To Be Packed | Granule / Biscuit / Jelly / Chips / Hardware Parts etc |

| Capacity | 15 - 50 sachet / min |

| Packaging Weight | Depends on Product |

| Film Width | 280mm |

| Bag Length | 30 - 200mm |

| Bag Width | 25 - 130mm |

| Film Material | Heat - sealable laminated film (e.g. OPP / PE , OPP / CPP , PT / PE) |

| Power Source | 200V / 50Hz / 2.2kW |

| Air Consumption | |

| Machine Weight | 320kg |

| Machine Dimension | L900 * W700 * H1900 |

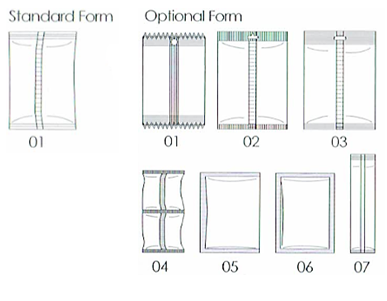

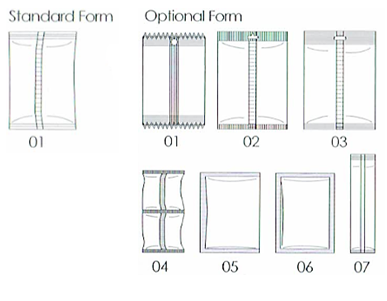

Form of Packaging

Untitled

Inquiry - EM-280B | Bucket Conveyor | SACHET PACKAGING MACHINE